PRODUCTION PROCESS

HR COIL

The process starts with the HR coils

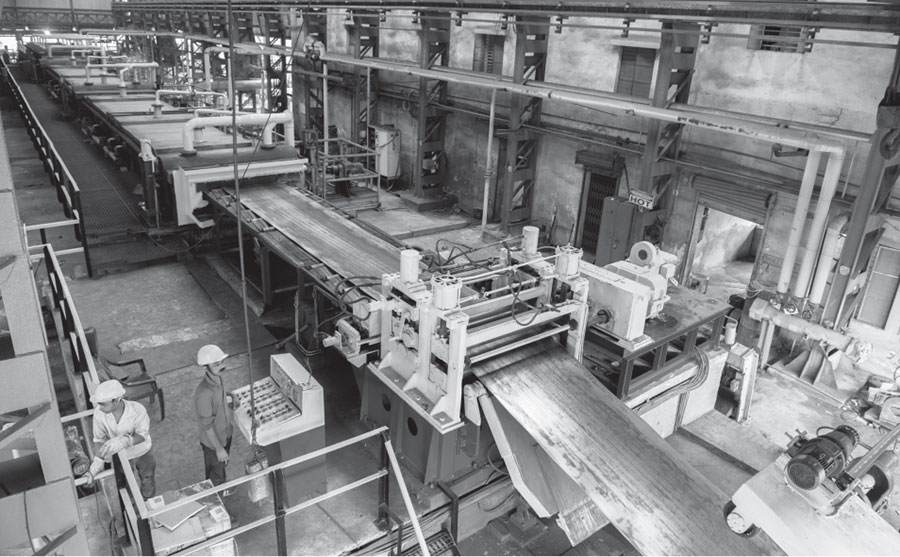

PICKLING LINE

Hydrochloric acid pickling line with a capacity of 180,000 mt per annum. The process removes oxide scales from the surface of the hot rolled coils.

- Through rinsing with DM water

- Chemical cleaning by hot acid of controlled concentration

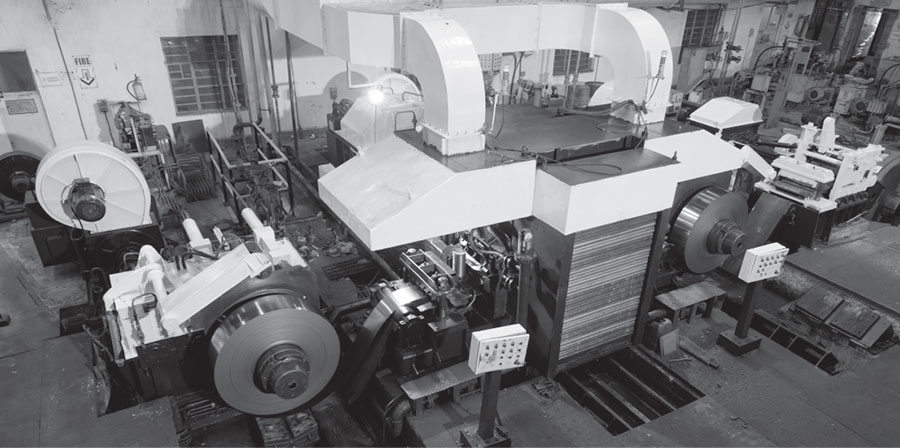

HR SLITTING

Pickled coils are slit to desired width to prepare narrow strips for further processing.

- Slitting line capacity is 180000 mt per annum

- Can slit up to 6 mm thickness

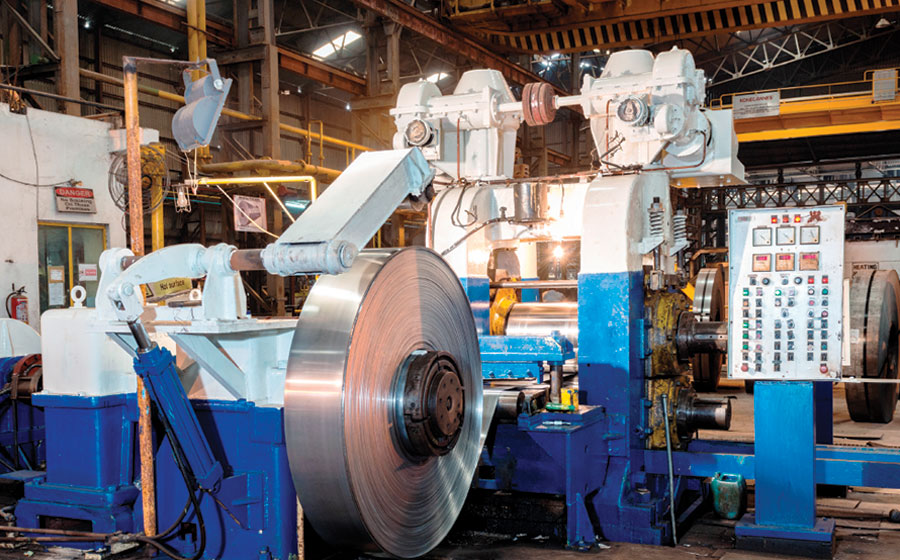

4 HI COLD ROLLING MILL

4–HI Cold Rolling Mill is used for rolling the pickled & slitted coils to their desired thickness based on requirements.

- Automated gauge control

- Output thickness range 0.30–4 mm

- Width range 400 mm(max)

BELL ANNEALING FURNACE

To remove strain and to obtain desired grain structure for improved mechanical properties. The strip is heated and control cooled in an inert atmosphere.

- Hydrogen and nitrogen gas used as inert media

- Superior surface cleanliness

- Spherodisation/Recrystallisation Annealing

- Mechanical properties as per IS standards

2 HI SKIN PASS MILL

Skin pass helps in slight thickness reduction to impart desired temper. Strip achieves desired surface roughness (matte, bright) as per customer specifications.

- Precise thickness control by experts

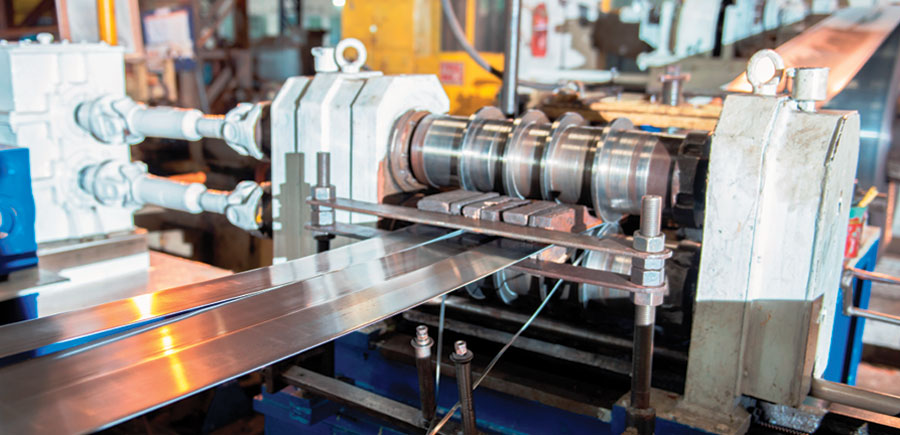

CR SLITTING

Cutting the coil to customised width as per requirements.

- It produces burr free edges with controlled winding tension

PACKING AND DESPATCHING

The products are packs carefully and are ready to be shipped.

WORKS AND OFFICE

Trishan Metals Pvt Ltd

Village Bamunari, NH–2, Delhi Road, Hooghly 712 250, West Bengal, India

P +91 90739 85924/93395 21039 E enquiry@trishanmetals.in